We solve: Data as part of the business of manufacturing

Satakunta has traditionally been a strong manufacturing region. Despite this, the value added of products produced in Satakunta has lagged behind most other regions. We therefore produce more bulk products than others, while the processing with higher economic value is concentrated elsewhere. However, the potential is there for us too, and we must exploit it now at the latest.

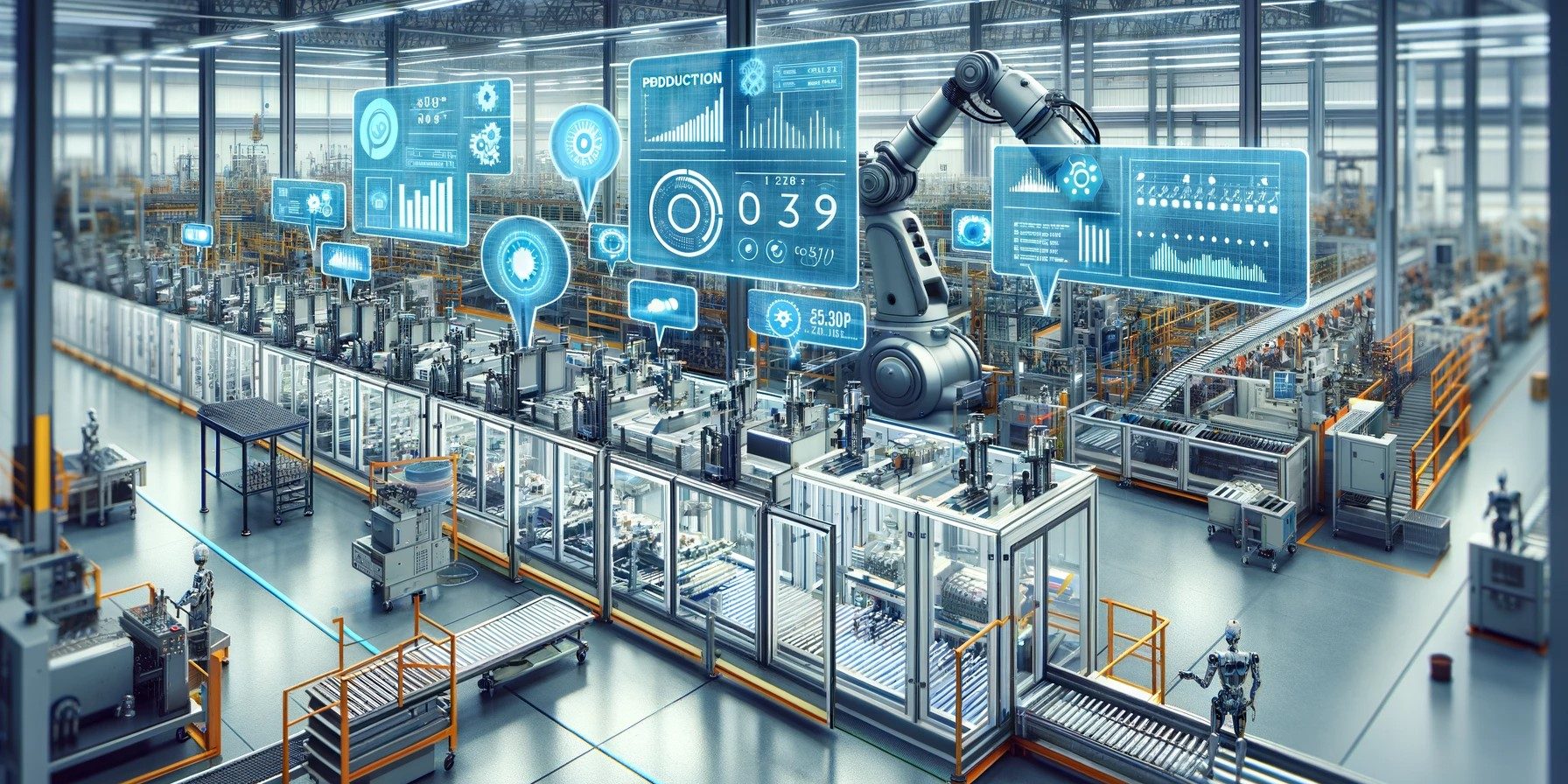

In addition to manufacturing physical products, companies accumulate a wide range of data during the manufacturing process. This includes product data from design, data from production and testing, data from information systems and, if the final product contains sensors or automation, also in-use data. Properly processed, all this data can provide new insights for improving production and efficiency, product development and innovation or, best of all, for creating a new business. Today, the most typical examples of new businesses are value-added services and (predictive) maintenance services. These are based on data generated by the use of the product, which, if analysed correctly, can be used to create added value. Equally, a company can use data to improve the efficiency and quality of its own production, both of which have a direct impact on profitability.

The most important factors in the use of data include

- finding the right sources of data - and also owning that data

- ensuring that the data is of high quality and that there is enough of it

- understanding what data you are dealing with and how to analyse it

- process the data into a limited number of data or metrics to begin with

- incorporate it into decision making

- share data within the company

- further process and produce more data

In general, companies see great business potential in the use of data. This is driven by a general increase in data awareness over the last five years. At the same time, however, it can be noted that the level of data analysis and visualisation is low. This creates a significant gap between the status quo and the target in all companies. The main barriers to better use of data are a lack of resources and skills for more advanced analytics and AI, and a lack of proven model solutions that could facilitate better allocation of existing scarce resources within companies.

Data experiments in DataBoost project

It is precisely this problem that the DataBoost project is addressing. It is a joint project of the Satakunta, Seinäjoki and Jyväskylä Universities of Applied Sciences to carry out various data experiments in the manufacturing industry. In practice, companies will provide the project with real production and product data, which the universities of applied sciences will use in their experiments. This will allow the development of mutual expertise in different analytical methods and knowledge of data analytics. Knowledge, skills and experience will also be shared between all actors involved in the project, ensuring that the benefits generated by the project will be exploited in the future.

About the writer:

My own background includes both entrepreneurship and specialist roles in a variety of industries. The common factor in all of these roles has been a lack of sufficient data to make the best decisions and follow up on decisions already made. Today this is already possible even in small companies, but it requires a new kind of skills, thinking and hindsight. The mission of the BIC is therefore to share knowledge and experience to help businesses in the region to be more successful.

Mikko Pakkasela is research manager in Research center BIC.